When inflating the high-pressure floor, a bubble automatically forms on the underside of the high-pressure floor opposite the air valve. This is not a production error but quite normal and technically conditioned. Logically, there is no drop-stitch weave in the bottom core of the valve area, which is why the bubble forms on the corresponding underside as the pressure builds up.

Neuer Text

General condition

Deviations in symmetry in the surface finish (wrinkles, bubbles, pressure marks, kinks, machining marks, colour deviations) as well as in the horizontal and vertical alignment and positioning of the individual components in relation to each other are due to design, physics and production technology. The dimensions and weights may deviate from the specified values by plus/minus 2-8% due to production technology.

Transom Plate + Transom Bars + Stern Flaps

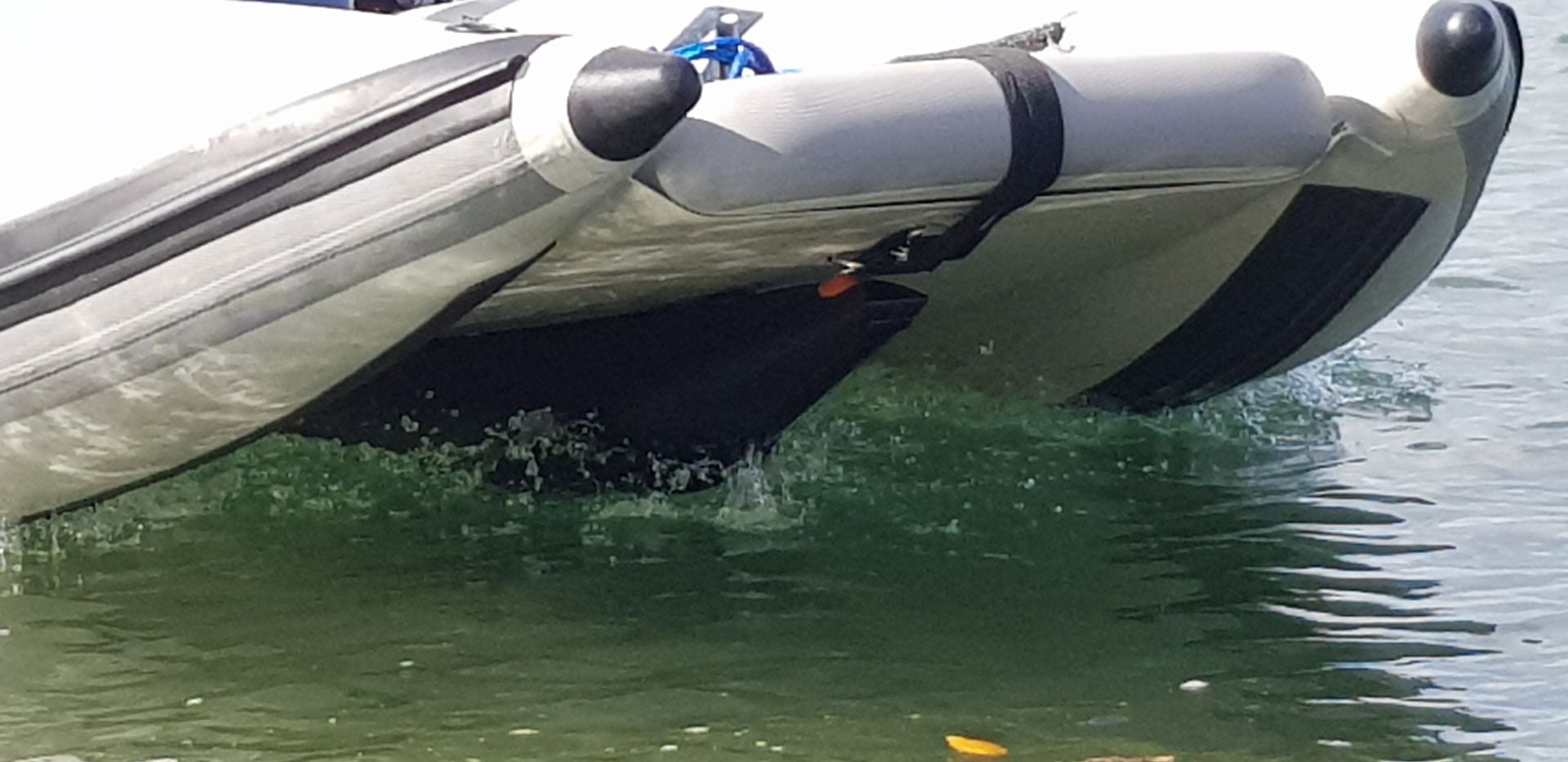

From "J020" onwards, the boats on port and starboard no longer have black stern flaps with Velcro fasteners, they have become obsolete in terms of design. Only the black tab in the middle has remained, it optimises the water flow below the transom plate.

The transom tubes are made of 304 (V2A) stainless steel. Due to its higher carbon content, it has a higher strength than 316 stainless steel (V4A) with the same wall thickness, but requires maintenance when operating in salt water. Stainless steel, whether V2A or V4A, is not, as is often claimed or assumed, resistant to corrosion, like gold or nickel, but can, thanks to its alloy components, like chromium, nickel and molybdenum, form a so-called passive layer in combination with the oxygen in the ambient air. This microscopically thin passive layer, approximately 0.6µ thick, is the true corrosion protection of stainless steel. Chemical (salt water - chlorinated compounds), mechanical (engine installations) or ionizing (transfer of foreign metal ions by wiping with a cloth on different metals) effects can selectively damage this passive layer. In these places, the stainless steel is no longer protected and corrosion spots form, which expand continuously, because in this area no passive layer can form.

Contrary to general opinion, stainless steel 316L (v4A) is no longer a seawater-resistant solution. According to Germanischer Lloyd, due to rising water and air temperatures worldwide, only the expensive high-alloy super austenitic stainless steels, e.g. 1.4539/AISI904L (X1NiCrMoCu25-20-5) and the duplex and super duplex steels (1.4462 / 1.4410), which have a mixed structure of ferrite and austenite, are resistant to seawater.

A first step when riding in salt water is to wash the transom hoses at the end of a trip with fresh water, including thorough drying. If the Takacat is used as a tender, it is not necessary to rinse the sleepers with fresh water before returning to the yacht, i.e. not always directly on the beach or in the port, except for multi-day trips.

The inner sides of the transom tubes can be pulled out using an extra long bottle brush. When using a bottle brush, ensure that the brush wire is also made of stainless steel (to avoid ionization).

If corrosion spots have formed, they can be removed using a stainless steel cleaner which also allows reconstruction of the passive layer.

If the boat must be driven continuously in salt water, it is advisable to spray the transom tubes and optional collector wheels with a seawater resistant stainless steel protector.

When installing an outboard motor, it is essential to ensure that the pressure plates of the toggle brackets on the outboard motor mount do not indent the transom top bar and cause any damage. structural damage. If necessary, use a spacer plate.

Important note for the installation of the two Transom Plates: The black rubber ring supplied must be installed between the two transom plates, i.e. the central screw is pushed through the central hole of the large transom plate, then the black rubber ring is pushed onto the central screw and then the two transom plates are screwed together. The black rubber ring reduces the vibration and the contact pressure between the two rear mirror plates. Lightly coat the last threads of the fastening screw with e.g. transparent Schmierfix from Liqui Moly. Slide the second washer onto the central screw and hand-tighten the ring nut.

The inner transom plate, after being pressed between the two transom tubes, should lie flat on the two stainless steel brackets and be centrally aligned. The transom plates are made of glued boat plywood with an additional protective coating. The wooden plates should be checked regularly to check that they are not damaged / abraded and repainted if necessary. Transom plates are not intended for use as permanent water storage. If the boat is to remain in the water for a longer period of time, the transom plates should be treated accordingly with an additional protective coating (e.g. synthetic resin coating) or designed as approx. 25mm thick plastic plate (e.g. made of PE1000). To prevent the motor mount from leaving marks on the large backplate, a protective PVC or rubber mat can be installed between the backplate and the motor mount. If the outboard motor is installed, the two stern mirror plates are strongly compressed against each other and the center screw connection is released. For this reason, the center screw should be hand-tightened after installing the motor so as not to lose it. If you want to uninstall the outboard, you must first loosen the center screw a little. By loosening the outboard toggle screws, the two transom plates logically relax again and the pressure on the center screw then becomes so great that it cannot be released manually.

If the connecting plate of the rear motor mount presses against the screw head of the transom mount, either a countersunk screw must be inserted or two spacer strips of at least 10mm thickness must be placed underneath, e.g. self-adhesive hard rubber strips - this solution also protects the transom plate from the motor mount brackets pressing into the wooden plate.

Slip Wheels for launching the boat

Slip wheels should be installed as shown at the very top of the picture gallery, i.e. they should roll inside. They must never pass under the transmission tubes on both sides, otherwise the tubes could be damaged. Slip wheels are only designed for the weight of the boat. Slip wheels are only designed for the actual slip process. They are not transport wheels or parking wheels. When the boat is parked, the slip wheels should be placed in the park position. For longer transport distances, as well as for more heavier engines, including luggage, boat carts are necessary, such as the "C-TUG Double" from RAILBLAZA - RAILBLAZA products are available worldwide.

Models with open bow - bow lashing

Depending on the weather and wave heights, the bow tips must be lashed down with a bow lashing. For this purpose, a lashing knot can be placed over the side D-rings or you can use one of the supplied tensioning straps.

Spray Water in Stern Area

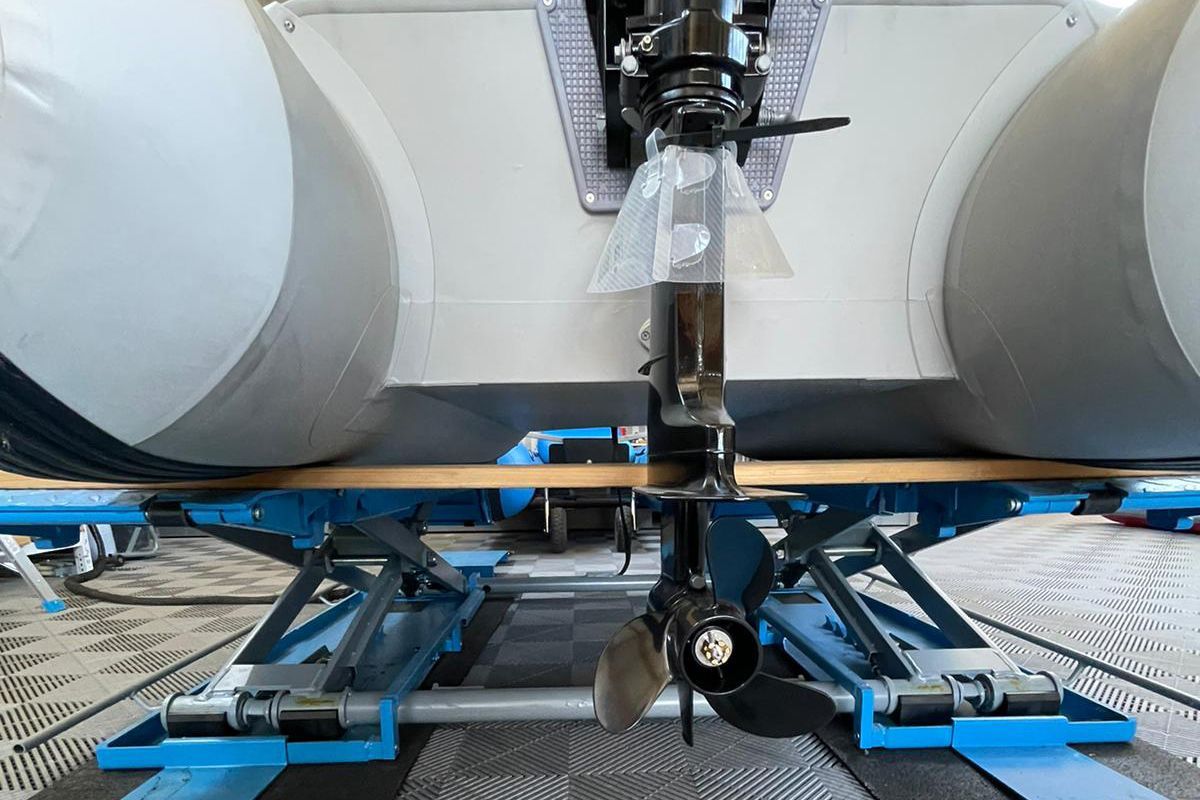

The upper transom rod has been lowered on the current models to eliminate ventilation at the propeller and reduce cavitation. Depending on the outboard model, shaft length, shaft design, water stop plate and trim position of the engine, more or less splashing water occurs in the stern area.

- First of all, the pressures must be checked. The boat must be in the water for this, as colder water temperature lowers the pressures. For maximum buoyancy, the drive hoses must each have a pressure of 3.6PSI and the high-pressure floor a pressure of 10PSI.

- Each outboard has at least one or two water stop plate(s) above the cavitation plate, at the rear of the shaft. This water stop plate must be above the water surface for it to be effective. When the boat starts, water flows against the shaft and tries to bubble up. The water stop bar stops the rising water. If the water stop plate is not above the water surface, the water rising from the shaft can bubble up to the motor housing and into the boat. If the water stop batten is below the water surface, the boat is either trimmed too stern-heavy (distribute load = neutral trim) or the shaft is longer than 15", e.g. Honda/Yamaha with 17" shaft.

- Attaching a water stop collar to the shaft (e.g. dog "Elizabethan Collar" - see photo above) prevents water from rising on the shaft.

- A very effective solution is to enlarge the existing water stop batten by adding an additional water stop batten with angled longitudinal edges. This is actually useful for many boats.

- A Permatrim Hydrofoil raises the stern faster and prevents the stern from dropping prematurely when the speed is reduced (larger sliding window), especially with larger stern loads. Model M4 for 4-6hp and M5 for 8-30hp engines.

- As a rule, the engine should be trimmed to the transom so that the stern is lifted more quickly, especially when the boat is driven with only one person.

- The new Speed-Tube (Wave Piercer) from Takacat lifts the boat and thus also the outboard. As a result, there is less shaft in the water and less splashing.

- A splash guard plate inserted between the two transom plates reduces the splashing water in the boat. However, you can also simply insert the roll seat crosswise in the stern and inflate it in the boat, thus fixing it to the transom as a splash water barrier.

Which Outboard Engine?

With the new lowered upper transom bar, a 15" short shaft is the optimal shaft length. Then the anti-ventilation plate (often called CAV plate) is located slightly below the so-called keel line, as can be seen in the picture above. Every outboard is equipped with at least one water stop plate on the back of the shaft to prevent the water from rising up the shaft. For engines from 8 hp, there are manufacturers who have equipped their engines with 2 x water stop plates. This is advantageous because the upper plate acts in the lower speed range and the lower plate in the upper speed range. In addition, the position of the lower plate has the effect of keeping the circular dispersion of the spray water in the lower transom area. In summary, this means that an outboard with a 15" shaft, 2 x water stop plates and the lowest possible weight is the optimal solution. I personally find the new Mercury F10EFI interesting because at 333cm it offers a higher torque than the F9.9EFI and can be optionally equipped with a ‘cupped’ stainless steel propeller.

An additionally installed Permatrim Hydrofoil not only results in a larger sliding window but also lifts the waterstop plate above the water surface earlier so that it can take effect. Especially for outboards with a 17" short shaft and only one waterstop plate at the rear, the installation of a hydrofoil is a must, so that no upflowing water overflows the transom via the radial shaft shape.

Small tip: with a 6HP outboard, a propeller with 7" pitch (higher torque) + Permatrim Hydrofoil is recommended. With this you can reach a comfortable planing speed even with 2 persons + luggage. For example, with one person a 340LX can reach 27Km/h (approx. 14Kn) and with 2 persons + luggage approx. 20Km/h (10Kn). The Permatrim Hydrofoil takes some speed but it reduces the glide angle by about 50% and increases the glide window to a glide speed of about 13Km/h (7Kn). Due to the larger glide window, speed and fuel consumption can be significantly reduced.

The use of a propeller with a lower pitch is also a possible solution against ventilation, see the following video:

Cupped Propeller

Propeller "cupping" is a technique to improve the performance of propellers under certain conditions, in this case a catamaran tunnel hull. If you notice "air sucking" (ventilation) then one countermeasure is to "cupp" the propeller edges and propeller tips, this increases rake and pitch and reduces ventilation because the propeller can hold more water in the same time window.

PowerTech, for example, offers factory "cupped" stainless steel propellers for many different outboards => https://www.ptpropeller.com/

Michigan Marine Propulsion (UK) in England also offers "cupped" propellers => https://www.mmp-i.com

Kirschbaum GmbH offers e.g. propeller "cupping" as a service => www.kirschbaum.at

Transport on the davits

One way to secure the boat to the davits is to put shackles through the wheel suspension holes on the lower transom tube. These can then be used as stern lifting positions. For the bow, a well-padded strap can be used to provide support under the boat. Normally this strap runs through the front grab handles on both sides so that the strap does not slip towards the bow or stern when lifting. Or a crossbar is installed on the high-pressure floor at the bow, to attach the bow lines, as shown in the slideshow above.

Side Splash Protection

The black rubber strips glued to the sides are not rub rails, they are the side splash protection. That is why they are installed so close to the water surface.

Bubble - High Pressure Floor

Fixing Seams

Electric Pump

Loss of pressure

The two carrying pipes of the Takacats are fitted with pressure relief valves at the rear. Thus, in the event of strong sunlight, a dangerous excess pressure is evacuated in order to avoid damaging the transport hoses. If the outside temperature drops again, the air pressures may no longer represent the correct values. Therefore, always check the correct air pressure values of the supporting hoses and the high pressure floor before each ride. If the heat changes during the day, always check the pressure values of all air-filled components and correct them to the correct pressure values to avoid damage. The high pressure floor is not equipped with a pressure relief valve. Therefore, avoid too intense sunlight on the high pressure floor and check and correct the air pressure values if necessary. If the annex is not in use, it is strongly recommended to store it in the shade or under a shelter to avoid excessive heating and an increase in the compressed air in the supporting tubes and in the high pressure bottom. An inflatable boat that remains inflated for several days can lose pressure. According to ISO 6185, a pressure loss of 20% within 24 hours is permissible.

In inflatable boats, the valve seats may settle slightly after production due to fluctuations and movements of heat, allowing air to escape. In this case, there are two valve keys in the repair box. The key with the smaller teeth is compatible with Halkey-Roberts air inlet / outlet valves, the key with the coarser teeth is compatible with both overpressure relief valves. Turn the valve insert slightly to the left with the appropriate valve wrench so that the lower sliding friction can take effect and then turn it by hand to the right.

VRING from Dr.SUP

If the outer valve seal ring still leaks despite being tightened, the VRING from Dr.SUP can help solve the problem. To do this, unscrew the valve head from the valve cage, slide on the VRING and screw the valve head back into the valve cage. The VRING compensates for unevenness, reinforces the sealing area and increases the tightness of the outer valve sealing ring.

Inner valve seal

If air escapes from the inner valve body, this can be checked again very easily by spraying with a soap solution. If bubbles escape from the valve after spraying, the valve must be unscrewed clockwise using the appropriate valve spanner and the sealing ring cleaned. Use the valve pin to set the valve to the ‘open’ position and swivel in lukewarm rinsing water. If necessary, lightly wipe the sealing surface with a damp Q-tip. With the safety pressure relief valve, the valve is opened by pressing against the valve from below and simultaneously swivelling the valve in lukewarm rinsing water. If this does not help, the valve insert must be replaced. When tightening the valve, always make sure that the valve spanner is always at right angles to the valve and is not tilted, otherwise there is a risk of it slipping and breaking off teeth.

Repair with liquid PVC

An interesting alternative to the classic repair of small holes and cracks with PVC skin and 2C PVC adhesive is the use of liquid PVC, e.g. Liquid-Patch or "Die Kleine Werft".

If a small hole is to be sealed with liquid PVC, the corresponding area must first be cleaned with a PVC cleaner and be free of grease. Then a pump is used to pump the air out of the corresponding hose chamber, thus creating a vacuum. The valve must be in the pump-up position so that it seals when the pump hose is removed. Then apply some liquid PVC to the damaged area. The vacuum will suck the liquid PVC into the damaged area, creating an additional deep seal. If the damaged area is larger and the inner fabric has been damaged, an additional mesh fabric must be applied. In this case, of course, the negative pressure method is not used.

Repair with workshop adhesive

Professional PVC repairs must be carried out with a 2K PVC adhesive to ensure that the glued joints hold permanently. The supplied 1K emergency adhesive is for short-term emergency repairs only. For boats made of Hypalon/CSM, a Hypalon/CSM adhesive must be used. Detailed instructions are available ONLINE from POLYMARINE. BENGAR's workshop adhesive is also very suitable for professional repairs and for gluing on additional components, the adhesive strength is very high. A big advantage, the Bengar glue is supplied ready to use, it does not need to be mixed extra. The necessary PVC cleaner is also included in the delivery. For the final bonding, a hair dryer is necessary, because this adhesive works with heat activation. The supplied 1K PVC emergency adhesive must be renewed annually, otherwise proper adhesive strength is no longer guaranteed.

Maintenance - Cleaning - Sevice

Regularly check valves, seams, straps, eyelets, rings, bolts, nuts and rudders on your Takacat. Pontoons are more alive than a plastic hull and constant movement can cause fatigue damage. It is important to keep the pontoons and high pressure floor adequately inflated. Insufficient chamber pressure leads to more water resistance and thus a reduction in speed. Regularly check the pontoon fastenings at the stern, hull and other joints of the tubes. In the case of dismountable inflatable boats, it is important that the surfaces and edges at the contact points of floors and pontoons are clean and free of dirt and stones so that friction does not cause damage to the contact points. The inflatable boats must not be exposed to sunlight without protection, this will damage the tubes. When not in use, the inflatable boats must be protected from direct sunlight (UV) with a suitable cover.

Cleaning of the hoses and the floor should be carried out at least once a year before storage. If dirt has accumulated during a trip or on the jetty, it can usually be removed most easily if it is cleaned promptly. Sand and silt can simply be rinsed off with clear water, see e.g. the cleaning video by Takacat. Thanks to the open transom, the water including sand and mud flows directly out of the boat. For cleaning other dirt spots, stains or streaks, a suitable cleaning agent, a soft brush and a sponge are recommended. When cleaning, never use strong force and high pressure on the boat parts, this can cause damage to the outer skin and the inner fabric. A variety of Inflatable Boat cleaning products with integrated UV protection are available on the market, for example from POLYMARINE. After cleaning, it is recommended to rub the tubes lightly with a dinghy finish to support the UV protection. The sun's UV radiation is getting stronger. What is generally not known: In light cloud cover with white clouds, e.g. fleecy clouds, the UV exposure is higher than in clear skies, due to the ground-cloud reflection.

Packing into the transport bags

In contrast to the illustration in the video, the tubes of the 460LX are quartered, i.e. the stern is laid on top of the bow and then half on top of each other again. That is why the 460LX's pack size is a little shorter, but it is a little thicker in height. The 460LX is then rolled up sideways and secured with the lashing straps.

Stability and manoeuvrability

Bimini

Bimini - 140cm length:

For the smaller models from 2.4m to 3m, the clip-on bimini offered by many boat dealers on the Internet is usually sufficient. It is simply attached to the rudder mounts and then fixed with the 4 tension straps. The disadvantage of this bimini is that the oars and the bimini can not be used simultaneously.

Bimini - 180cm length:

For the larger boats, the bimini should have a length of at least 180cm, see e.g. from OSCULATI. Please note that the width has to be not more than 130-140cm so that the bimini holder can still be functionally glued onto the tube, as shown in the photos above. The bimini bracket must be glued onto PVC hoses with a 2-component PVC workshop adhesive. The RIB port from Railblaza with integrated cleat is interesting as a bimini bracket, available as a complete set with RIB bracket + 2K PVC workshop adhesive from Lotu.

Fender cushion "FlexiCush":

The fender cushion shown in the first photo is a FlexiCush - It can be ordered from many dealers on the Internet.

Heavy-Duty Oar Holder made with Stainless Steel

The company Imperial Fishing GmbH offers a Heavy-Duty Oar Holder made with Stainless Steel:

Working temperature range

A working temperature range of minimum -20°C to maximum +60°C applies to all boats and kayaks made of PVC. These values must not be exceeded or fallen short of.

Towing

Only the towing rings at the stern and at the bow (the two fixing rings under the floor at the bow) are used for towing. The optimal solution would be to glue two large towing rings at the bow under the connecting floor. When towing, it is essential to ensure smooth throttle changes. Rough jerky throttle changes can cause damage. The transom tubes must never be used as towing brackets.

Velcro fasteners - Repair

The Velcro fasteners consist of a cushion strip and a tooth strip. The cushion strip becomes clogged over time, e.g. by sand and salt crystals. Brush the cushion strip lightly with a toothbrush to remove the sand particles and salt crystals. Brush the tooth strip against the grain with the blunt back side of a knife blade, thus straightening the individual teeth. The PVC is a thermoplastic, which means that if it is heated with a hair dryer, the shape can be made a little rounder. Always wave the hairdryer on level 3, do not point it at one spot for a long time so that the PVC is not damaged.

Speed-Tube - Wave-Piercer

The Speed-Tube is fixed in the inflated state (250mbar / 3.6PSI), under the connecting floor, with the supplied tension straps to the bow fixation and to the lower transom pole in the middle.

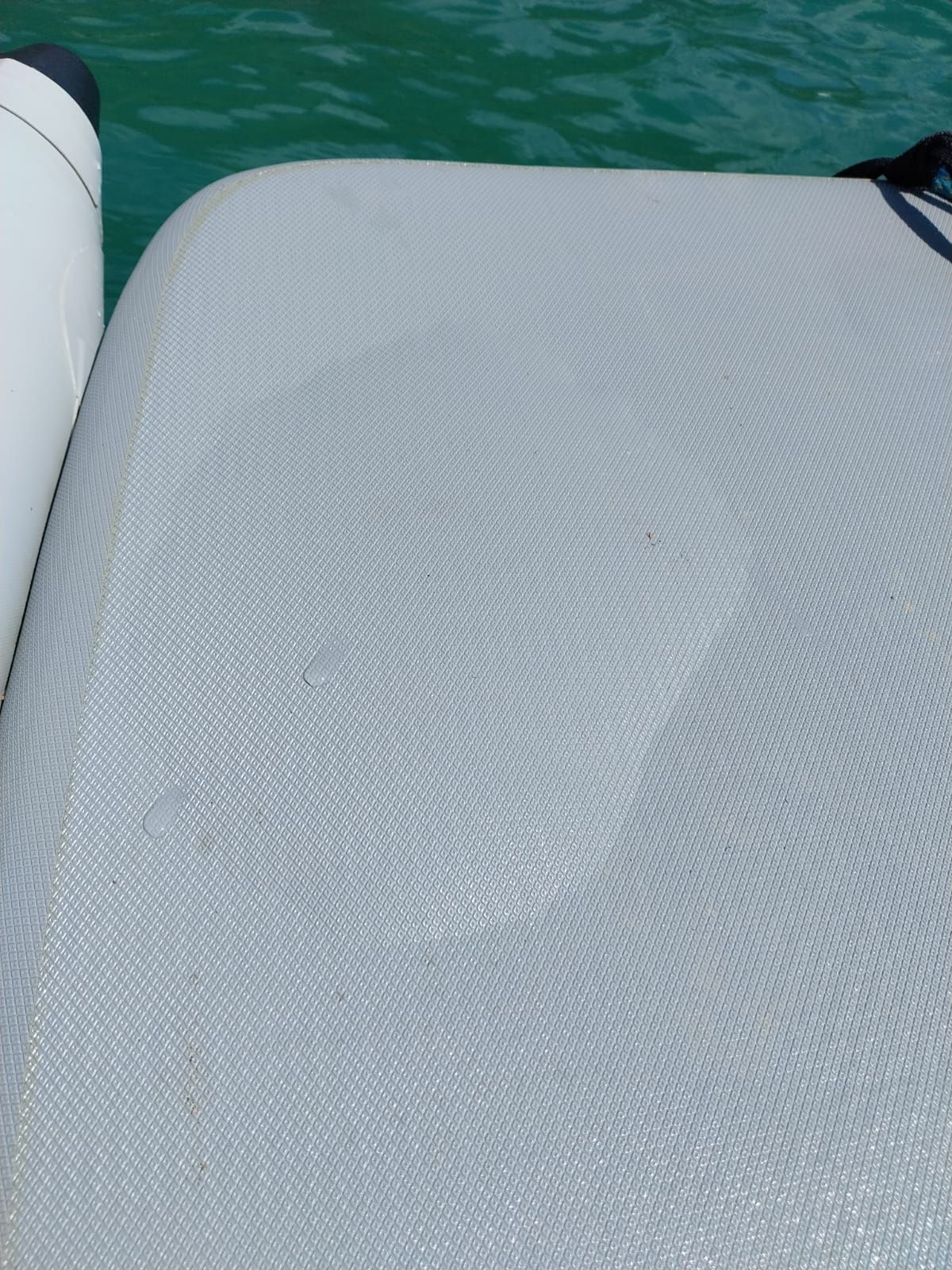

Whitish Kinks

The whitish kinks occur when PVC is unfolded in a cold state. This does not affect the function. Since PVC is a thermoplastic, the kinks will reharmonize when exposed to sunlight (heat). The kinks can also be smoothed with the help of a hair dryer. Use a hairdryer with heat level 3 and a workshop dryer with heat level 1, and always make sure that the PVC is not overheated. Finally, rub the kinks lightly with ethyl ester, see video.

UV-rays - Chaps + Cover

The sun's UV radiation is getting stronger and stronger. Continuous exposure to UV radiation can burn the PVC/TPU skin within a short time and lead to surface changes. Thin layers of cloud or fog hardly weaken the UV radiation and can even have an intensifying effect due to the reflection of UV radiation reflected upwards from the water or ground. If the boat is stored on land or on deck, regardless of its position, or is permanently attached to the davits, it is essential to protect the boat from UV radiation with a cover or chaps. The covers are available as standard for all models. The chaps must be customised, as the valves, D-rings and handles are positioned slightly differently on each boat. We recommend contacting a local sailmaker for the chaps so that they can be cut to size directly on the boat.

Oar Holder - Ball Head Nut

The ball head nut must not be twisted when it is put on, otherwise the internal thread will be damaged. It must be easy to unscrew. As a rule, only tighten lightly, especially when it is hot, otherwise the threads may become caked after cooling. The threads must be clean and free of sand or salt deposits. It is very advantageous to rub the internal thread with a little sour-free marine grease so that the thread remains flexible. If the nut is stuck, please do not use force, a little penetrating oil works wonders.

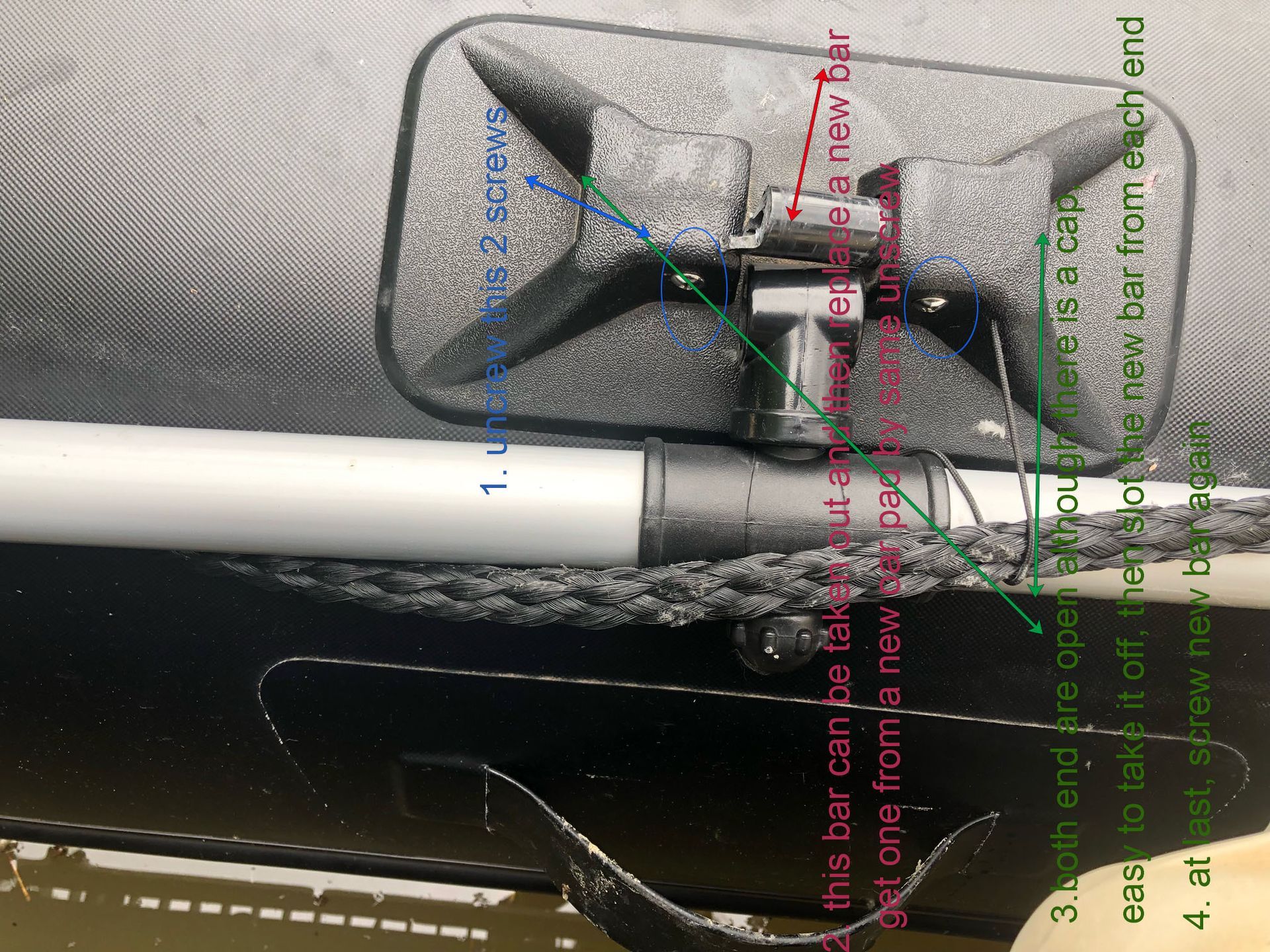

Replacement of the oar holder mechanics

The replacement of the oar holder mechanics is carried out as follows: 1) Loosen the two lateral fixing screws. 2) Remove the two lateral cover caps. 3) Push out the joint tube from the side. 4) Slowly push in the new joint tube until it reaches the recess. Insert the rudder mount in alignment and push the joint tube further in as far as it will go. 5) Replace the two side caps. 6) Screw in the two lateral fixing screws again.

Replacement of the complete Halkey-Roberts valve

If a complete replacement of the Helkey-Roberts valve has to be done, e.g. because the replacement valve is not compatible with the inner valve cage or because the inner valve cage has been damaged, then the video above shows the non-destructive solution.

Detachment due to heat exposure

In summer, surface temperatures can exceed 80°C when exposed to direct, unprotected sunlight. This is particularly true for black objects, such as oar holders and protective strips, due to their complete absorption of the sun's rays. The softening temperature of PVC is approx. 80°C, i.e. the PVC skin and thus also the adhesive yield at these surface temperatures, resulting in heat-induced detachment. For this reason, boats must not be exposed to sunlight for long periods of time without protection, as can happen, for example, on davits or when stored on deck. Cover the boat if it is not in use. Do not check the softened adhesive bond when it is excessively hot. The adhesive bond must first cool down so that the adhesive regains its adhesive strength within the operating temperature range.

Holding Lines

The holding lines on the inside and outside of the inflatable boat are not carrying lines, i.e. they can only be loaded in the transverse direction. If you grab the end of the line and pull it lengthways, the end of the line can be pulled out with its spike. Once this has been done, the spike can simply be inserted horizontally back into the line in the same way as the other line ends. The line ends are not spliced in so that in the event of a repair to the D-ring pads, the retaining lines can be opened without causing damage.

High-Pressure Floor - Heat Bubbles

The ribbed PVC protective coating of the high-pressure floor is bonded to the drop-stitch skin over the entire surface. Air pockets inevitably form during the bonding process. When a boat is exposed to sunlight without protection, surface temperatures of 80°C or more are reached and the trapped air expands. The resulting heat bubbles can be removed as follows:

- Inflate the high-pressure floor to full operating pressure.

- Either pierce the upper part of the bubble horizontally with a cannula or carefully make a small incision at the apex of the bubble with a scalpel/cutter knife.

- Heat the bubble to approx. 50°C with a hair dryer (setting 3) and squeeze the bubble out with a small hand roller or the back of a spoon, taking care not to press on the cannula. When heating the bubble, always move the hair dryer back and forth; do not point it at one spot, as this can cause the PVC material to overheat.

- Finally, pull the cannula out again.

To prevent a boat from suffering heat damage, it is essential to cover it during storage. Even a large bath towel is very helpful.

High-Pressure Floor - Safety Valve

For high-pressure floors equipped with an additional pressure relief valve, please note that the internal pressure drops after cooling and must be pumped back up to the required operating pressure.

CAT-Trailer - Example

Charge your battery with the sun

More range – more freedom – more independence.

In this video, we introduce you to the brand new FLINdinghy system – a smart mount that allows you to easily attach your FLINpole+ solar module to your inflatable boat. This allows you to charge your electric motor directly with solar energy while on the go. Perfect for anyone who wants to be independent – whether you're going ashore, fishing or on longer trips .....

More Information

Choosing the Right Material for your TAKACAT Inflatable Boat:

A Comparison of PVC, Hypalon, and TPU Fabrics

When looking to buy a new inflatable boat, one of the most important decisions you'll make is the material it's built from. At Takacat, we understand that different adventures require different boats, which is why all our models can be manufactured in your choice of PVC, Hypalon, or TPU fabrics. Each of these materials has distinct characteristics that affect durability, weight, cost, and overall performance. To help you make an informed decision, we have outlined a detailed comparison of PVC, Hypalon, and TPU fabrics and how it will work on your new Takacat inflatable boat.

PVC (Polyvinyl Chloride)

- Composition: A synthetic plastic polymer, often reinforced with polyester or nylon mesh.

- Durability: Offers good resistance to abrasions and punctures, but it is less robust than Hypalon. It has moderate UV resistance and can degrade over time with prolonged sun exposure unless a UV stabiliser or cover is used. However, our Takacat "Sijiatex PVC" is manufactured with a UV-resistant stabiliser to enhance its longevity.

- Weight & Portability: Lightweight, making it easier to handle and transport.

- Lifespan: You can expect a lifespan of 5-10+ years with proper care.

- Cost: The most affordable option. Boats made of TPU cost approximately 35% more than boats made of PVC.

- Maintenance: Easy to repair with adhesive patches or widely available repair kits. All materials require proper cleaning, storage away from direct sunlight, and regular inspections to maximise lifespan.

- Customisation: PVC is easier to manufacture in various colours and designs.

- Best Use Cases:

Ideal for budget-conscious buyers, recreational boating, calm waters, and occasional use. It's a great option for a family prioritising portability.

Hypalon (CSM - Chlorosulfonated Polyethylene)

- Composition: A synthetic rubber with a neoprene base, coated with chlorosulfonated polyethylene.

- Durability: Exceptional durability and highly resistant to abrasions, punctures, and harsh conditions. It boasts superior resistance to chemicals, oils, and fuels, making it ideal for harsh environments.

- Weight & Portability: Hypalon is heavier than PVC, which can make boats less portable.

- Lifespan: With proper maintenance, a Hypalon boat can last 10-20 years or more.

- Cost: More expensive due to its superior durability and longevity. Hypalon boats cost slightly more than twice as much as PVC boats.

- Maintenance: Repairable but requires specific adhesives and expertise. Hypalon demands more careful maintenance due to its cost and longevity. All materials require proper cleaning, storage away from direct sunlight, and regular inspections to maximise lifespan.

- Customisation: Hypalon is available is several colour options and can be customised.

- Best Use Cases: Perfect for commercial, military, or heavy-duty use in extreme environments, such as the tropics. This is the ideal material for event organisers needing a tough and reliable safety boat.

TPU (Thermoplastic Polyurethane)

- Composition: A thermoplastic elastomer that combines flexibility and durability.

- Durability: Offers very good durability with strong resistance to abrasions and punctures. Its UV resistance is very good, better than PVC, though slightly less than Hypalon.

- Weight & Portability: Lightweight, similar to PVC, which enhances portability.

- Lifespan: The expected lifespan is 7-15 years, depending on quality and maintenance.

- Cost: Moderately priced, more expensive than PVC but often cheaper than Hypalon.

- Maintenance: Easy to repair with heat welding or adhesives, and repair kits are becoming more common. All materials require proper cleaning, storage away from direct sunlight, and regular inspections to maximise lifespan.

- Customisation: TPU is easier to manufacture in various colours and designs.

- Best Use Cases: A versatile material suitable for both recreational and semi-professional use, and a great choice for eco-conscious buyers. It maintains flexibility across a wide temperature range, making it suitable for varied climates.